Professional manufacturer of automatic bottle cap production line

Professional manufacturer of automatic bottle cap production line

-

Qualityassurance

-

On-demandcustomization

Professional manufacturer of automatic bottle cap production line

Professional manufacturer of automatic bottle cap production line

Qualityassurance

On-demandcustomization

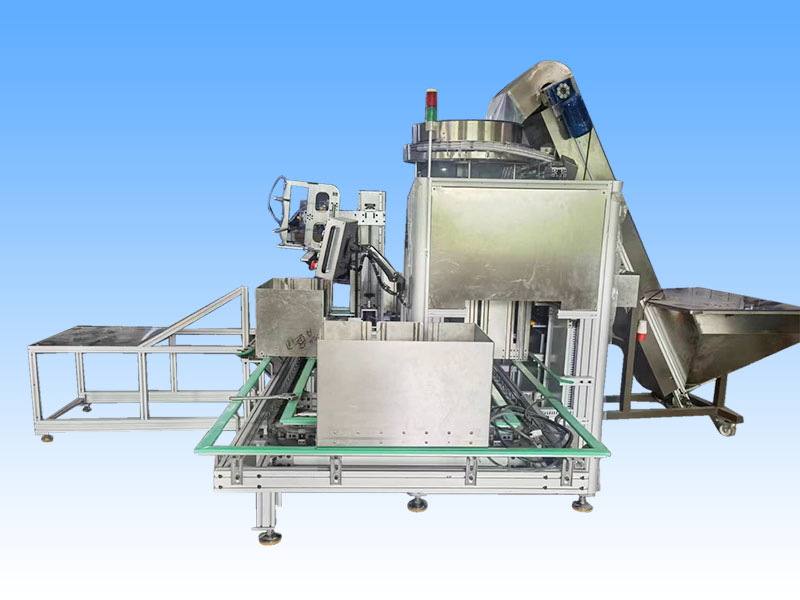

Automatic packing machine in the packaging industry to provide a great help, it greatly improves the efficiency of the packaging, so how much do you know about the structure of the automatic packing machine?

1. From the power output, the operation of the transmission mechanism, to the action of the work actuator, and the coordination cycle between various agencies, etc., are controlled by the control system, so the control system is the core of the entire food packaging machine.

2. The power part of the original power of the packing machine, which is usually based on the motor in modern industrial production, of course, in individual cases, there are also the use of combustion engines or other power machinery. With the supporting is the transmission mechanism, its role is to transfer power and movement for the food packaging machine, mainly including gear, CAM, sprocket, belt, screw, spiral worm and other transmission parts.

The important value of automatic packing machine

At present, the domestic packaging machinery has developed very rapidly, of which the automatic packing machine has played a key role in modern production.

1. Reduce labor intensity and improve working conditions. The use of packaging machinery can not only save workers from cumbersome labor, but also greatly improve the working conditions of workers.

2. It is conducive to the hygiene requirements of packaging products, avoiding direct contact between hands and drugs and food, and reducing the pollution of products. The packaging speed is fast, and the food and medicine stay in the air for a short time, which reduces the chance of pollution and is conducive to the health of food and medicine.

3. Protect the environment, save raw materials, reduce product costs. The use of mechanical packaging can prevent the loss of products, since the protection of the environment, but also save raw materials.

The application and development of packaging machinery is conducive to promoting the development of the packaging industry and improving the quality of life of the people.5. Reduce the area of the packaging site, save construction investment, use automated production and packaging line, the supply of products and packaging materials are more concentrated, the packaging process arrangement is more compact, save the packaging site and storage area, and improve the process and process conditions of the packaging.

6. Extend the shelf life of the product and facilitate the dredging of the product.