Professional manufacturer of automatic bottle cap production line

Professional manufacturer of automatic bottle cap production line

-

Qualityassurance

-

On-demandcustomization

Professional manufacturer of automatic bottle cap production line

Professional manufacturer of automatic bottle cap production line

Qualityassurance

On-demandcustomization

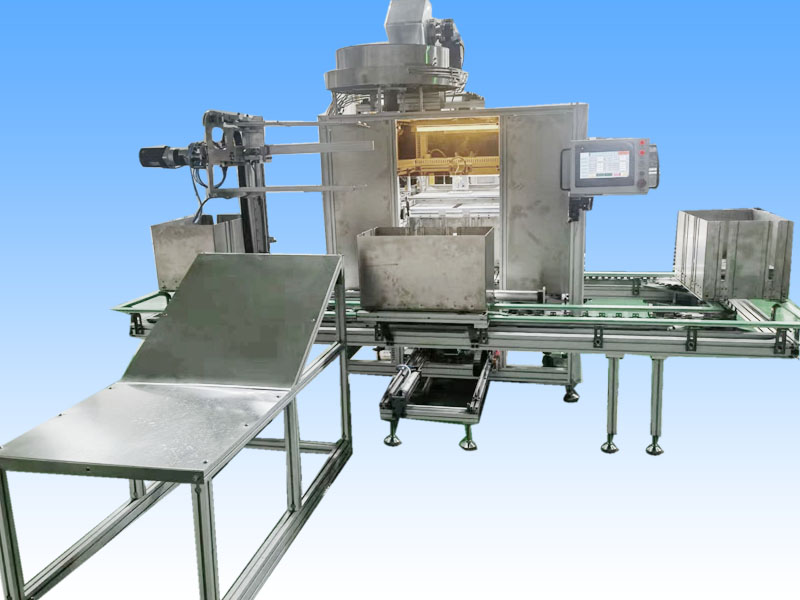

Robot packing machine is a semi-automatic or automatic loading of unpackaged products or small packaged products into transportation packaging equipment, its working principle is to load the products in a certain arrangement and quantity into the box (corrugated carton, plastic box, pallet), and close or seal the opening part of the box.

The choice of packing machine can generally be considered from the following aspects:

1. Mechanical structure: The collection, sorting and bunching of products are the key to the packing machine, so users should pay attention to whether the mechanical structure of the packing machine can meet the production needs of users before purchasing. In addition, according to the different packing methods of the product, there are generally four optional packing methods: grab, clip, suction and push, and users should choose a good packing method according to their needs before purchasing.

2 Automatic control: The control system is the guarantee of the normal operation of all functions, but also the automatic protection of failure and accidents, so the user should know how to set the control system in detail when choosing.

3. Production speed: Whether it can meet the production requirements.

4 Internal configuration: good configuration can ensure a good product, so users should pay attention to whether the internal configuration of the selection of good quality accessories.

Packing machine features:

is an intelligent automatic packing machine, using high-speed distribution device to pack a variety of containers, packaging plastic flat bottles, round bottles, irregular bottles, various sizes of glass bottles, round bottles, oval bottles, square cans and paper cans, etc., in addition, it is also suitable for packaging boxes with partitions. The bottle holder (built-in rubber to prevent damage to the bottle body) holds the bottle body (2 cases each time) and puts it into the open carton. When the grab head is lifted, the carton is discharged and sent to the box sealing machine, which is controlled by P.L.C + touch screen. With a lack of bottle alarm stop, no bottle does not pack safety device. This assembly line is greatly convenient to operate, manage, reduce production personnel and labor intensity, servo packing machine is an essential equipment for automatic large-scale production.

● According to the packing requirements, the product can be automatically sorted and arranged.

● Novel design and compact structure.

● Wide range of application, can be applied to a variety of products packing.

● Especially suitable for use with packaging line, easy to move.

● Computer program control, simple operation, stable action.

● Bottle class, box class bag class, bucket class series.