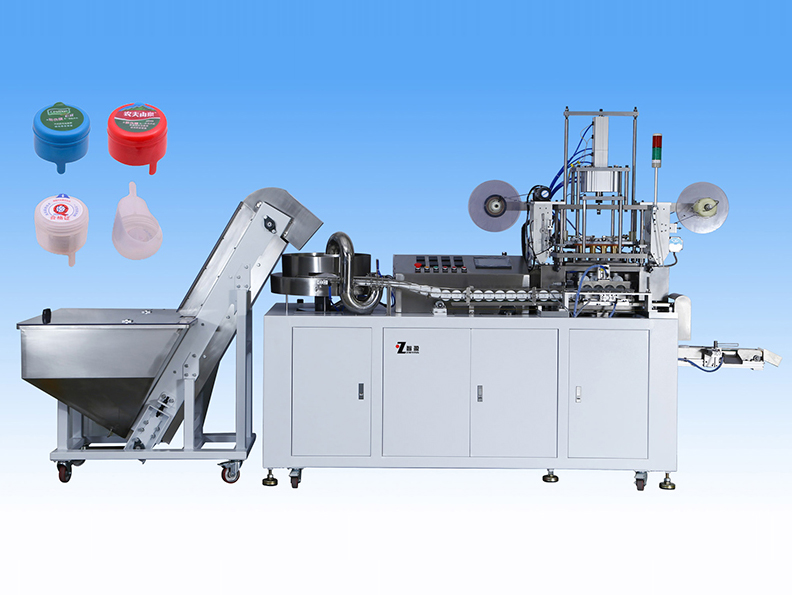

Professional manufacturer of automatic bottle cap production line

Professional manufacturer of automatic bottle cap production line

-

Qualityassurance

-

On-demandcustomization

Professional manufacturer of automatic bottle cap production line

Professional manufacturer of automatic bottle cap production line

Qualityassurance

On-demandcustomization

First of all, the daily chemical products industry is widely used, the products of this industry have high requirements for product appearance and packaging, so the label needs to be pasted more beautiful, neat, no folds and bubbles. Only in this way can the strength of the brand enterprise be demonstrated, and this can only be achieved by automatic labeling machines such as labeling machines. In addition, the product shape of the daily chemical industry is relatively variable, so a labeling machine that is more inclusive of the shape of the labeled product is needed to complete the labeling work. However, not all automatic labeling devices are highly versatile, so universality should be considered when purchasing labeling machines, which can be compatible with various bottle shapes and sizes to meet the needs of rapid replacement of various labels.

Let's look at another industry that has a huge demand for automatic labeling equipment. That industry is the food and beverage industry. In both industries, product packaging is more stringent. As consumers pay more and more attention to food safety, labels should not only be beautiful and generous, but also require clear information such as production date and batch number, or complete traceability information. When purchasing labeling, in addition to beautiful labeling and positioning, other supporting requirements should also be considered, such as coding function, coding function or docking line production.

Since the food and beverage industries have high requirements for labeling, the pharmaceutical industry is no exception. Like the daily chemical industry, the pharmaceutical industry has a very diverse range of products, and like the beverage industry, labeling is very fast. Because their daily production volume is very high, they must complete thousands or even tens of thousands of labeling operations per hour. At the same time, it is also necessary to consider the traceability of the match, or the automatic packaging of the docking equipment. Therefore, this industry also has high requirements for products. The same is true in electronics. As a fast-moving consumer goods industry, exquisite packaging is naturally indispensable. For delicate packaging, the precision of the label is very high. Accurate positioning and labeling are crucial.

With the continuous development of science and technology, new equipment continues to emerge in recent years. In this industry, new products are indeed easier to use than traditional machines. Semi-automatic labeling machine is one of them, and its emergence has also attracted the attention of the industry. Next, we will show you the advantages of semi-automatic labeling machines.

Today, many product processing centers use semi-automatic labeling machines. The semi-automatic labeling machine attracts many manufacturers with its high precision and reliable performance, which is also its main advantage. The semi-automatic labeling machine can be loaded automatically during operation. Therefore, we have done a good job in this regard. Manufacturers are also constantly improving, which greatly increases its capabilities. In addition, acme screw drive is used in production, which is made of one roll, making the semi-automatic labeling machine more accurate.

In addition, the overall structural design of the semi-automatic labeling machine is very simple, and there is no lower transmission link when rotating, which is also one of its advantages. In fact, these devices were not available before. It can be seen that the characteristics of the semi-automatic labeling machine are very prominent in different places. With these words, the operation is more convenient. In fact, the reason why it has been so successful in the field of automation is because it is concise and accurate. Compared with the transmission mechanism, the semi-automatic labeling machine undoubtedly has a higher transmission efficiency.